Measuring Technology

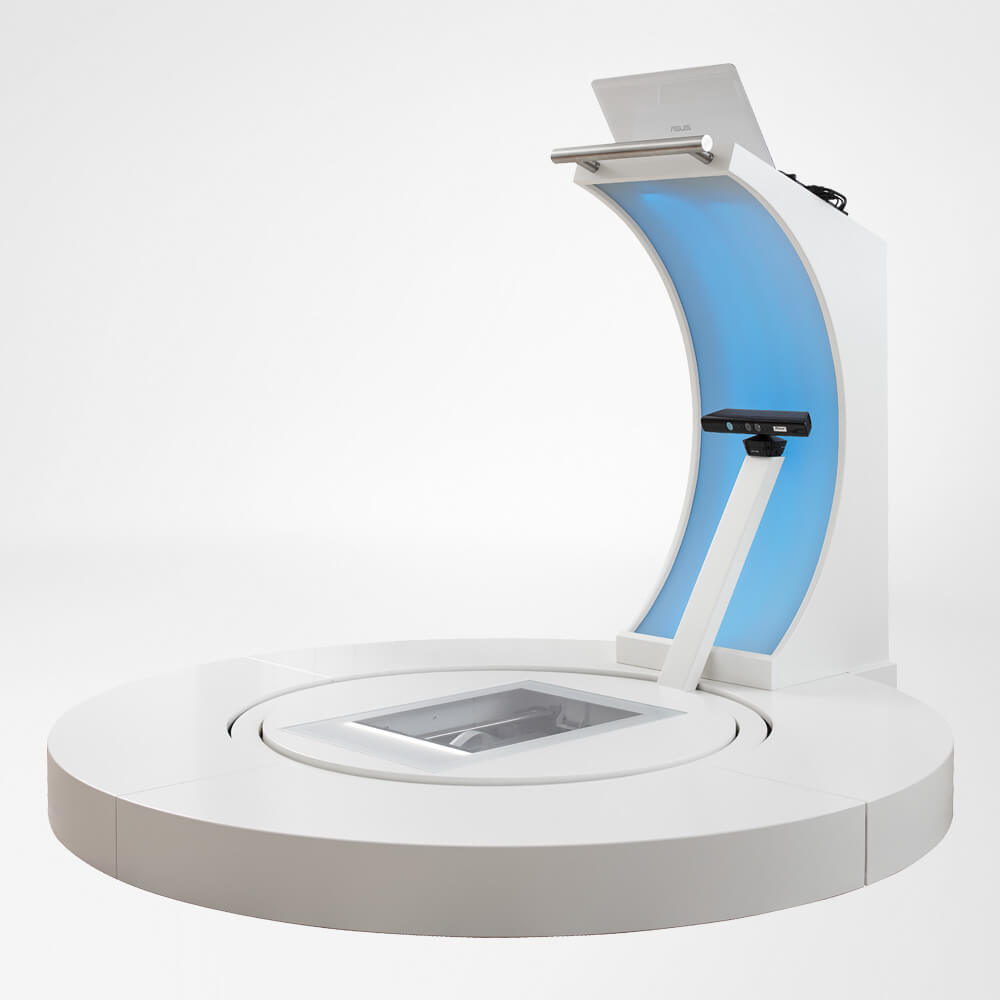

Bodytronic® 400

Better measurements ensure the best care

The integrated foot scanner allows us to offer orthosis products. The foot-scanning data obtained with the Bodytronic 400 is synchronized directly with Bodytronic ID:CAM, where the data is used to model a Bauerfeind milled orthosis. This foot scanner as well as the Voxelcare Milling machine is within our fascilities and ensures a fast (within one day), effective milled insoles.

Medical compression stockings help with tired and heavy legs. They are the most important method of treatment for chronic venous insufficiency and after varicose vein surgery. Highly precise digital measurement of legs ensures a perfect fit, as well as a high degree of wearing comfort, all of which adds up to better treatment results. Such accurate digital measurements also saves valuable time, meaning more time can be spent on choosing the correct product.

CONTEMPLAS TEMPLO® Video Analysis

In addition to our Bauerfeind measurement technology, we also use Video Gait analysis. This analysis is mainly used for athletes that do various sport to assess the way they walk and run. After database entries have been created with all relevant information, athletes are instructed to run normally on a treadmill while they are captured from several camera perspectives. After the capture, the Podiatrist can review the videos and measure knee angles, the degree of pronation. In addition, synchronized three-dimensional force data Medilogic 150 can also be analyzed alongside video data within TEMPLO. All information can then seamlessly be inputted into customized report pages and given to the patient.

Bodytronic® ID:CAM

When designing insoles for milling, the Bodytronic® ID:CAM is the software choice. The 2D and 3D data that is captured by the BODYTRONIC® 400 is used to design the insoles individually for the patient.

With the three Bodytronic® ID:CAM profiles, we can decide which steps in the orthosis production process we would like to hand over to Bauerfeind. The integrated and modifiable model and module library helps reach our chosen care objective quickly and efficiently. The design of the insoles are then sent to our Voxelcare CNC milling machine that will produce the insoles within 20 minutes.

Thanks to fast production and delivery times, patients can be treated even more quickly.